color chart

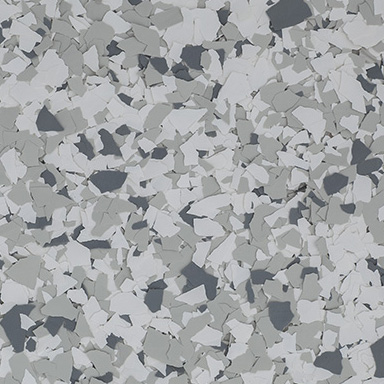

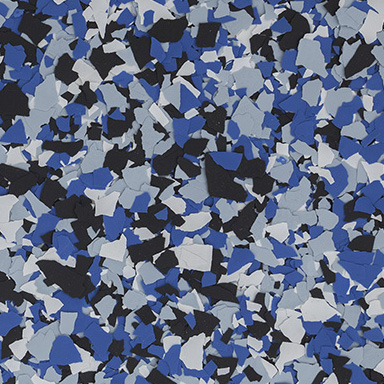

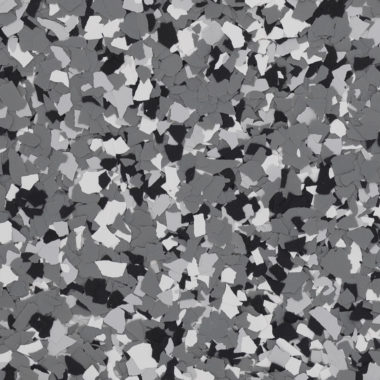

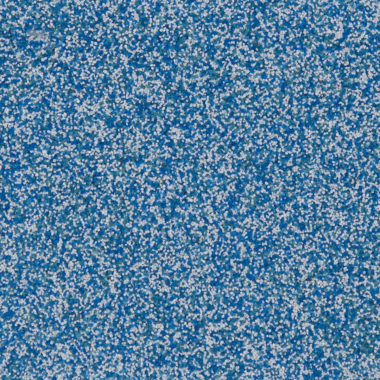

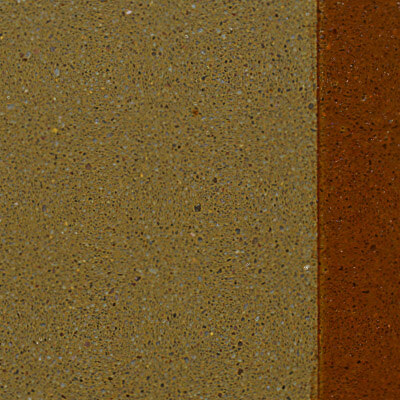

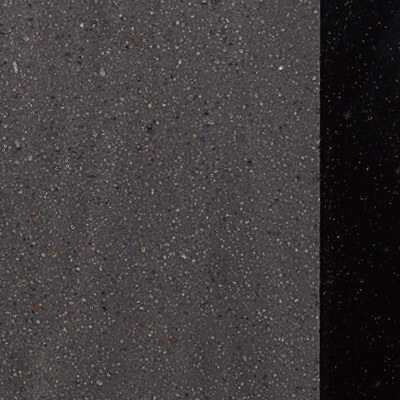

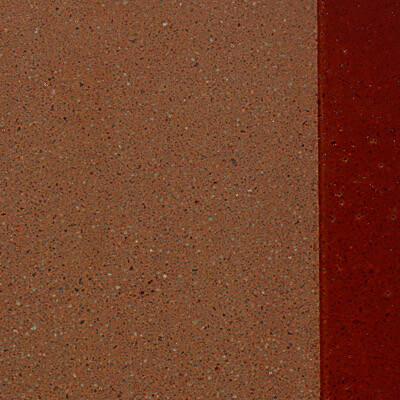

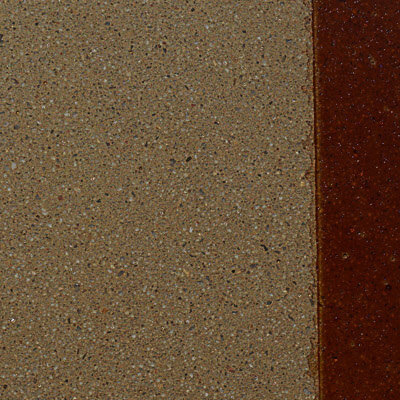

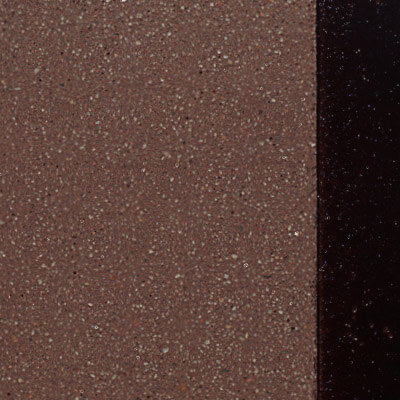

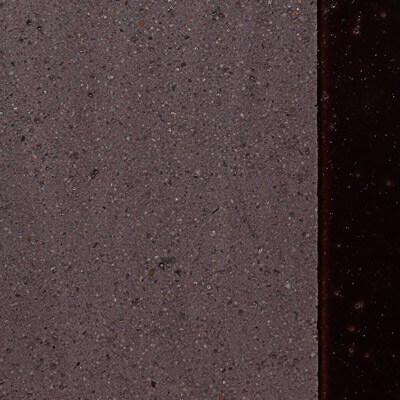

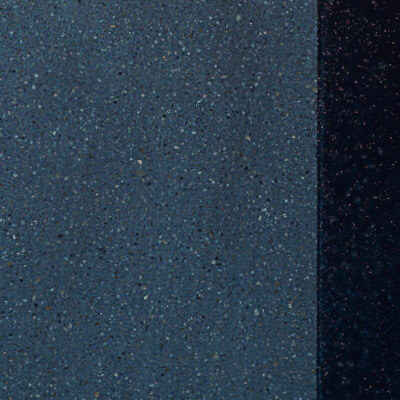

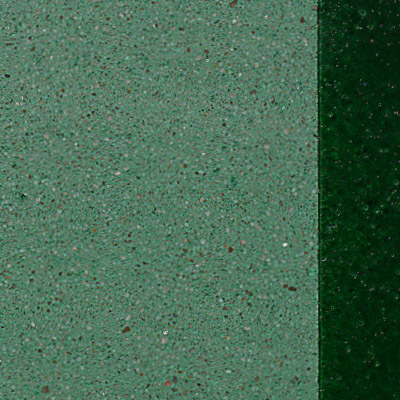

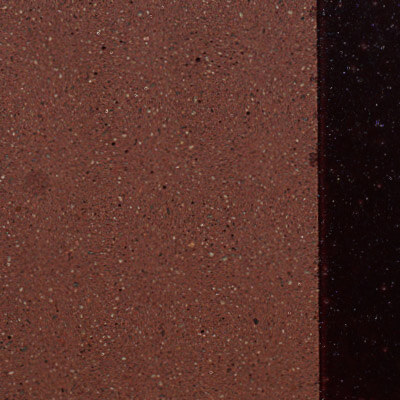

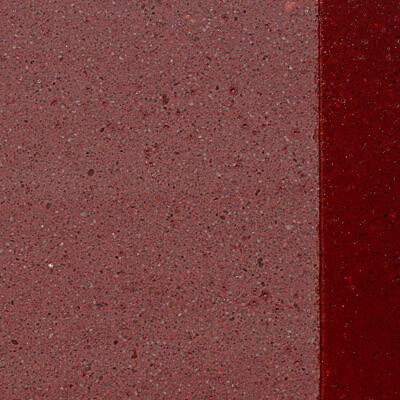

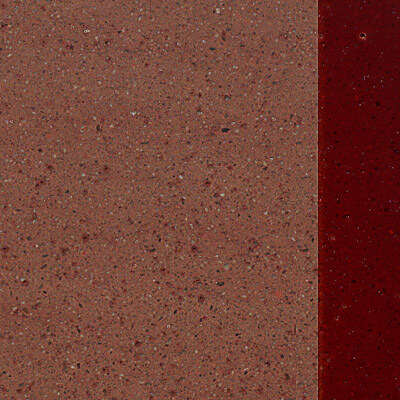

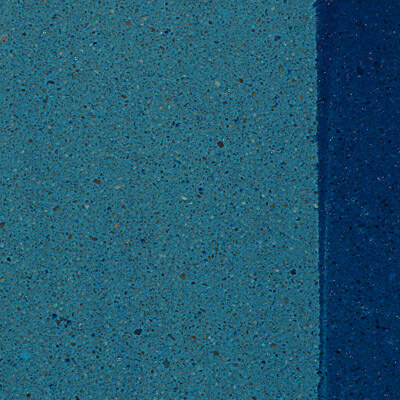

Quartz Flooring Color Chart

Concrete Stain Color Chart – Acid

What are the necessary steps for color chart?

Then it comes to the polishing portion which is the labor-intensive iterative process. This requires various different levels of diamond grit, starting from a lower grit, such as a 30 grit level. Then it goes up in diamond grinding stages that will continue up to a 1,500 to 3,000 grit level, depending on how shiny the floor needs to be.

Any divots that form will need to be filled in during the grinding and polishing process above to continue with that smooth surface. In addition, a hardener or densifier needs to be applied periodically to reinforce the surface, forging the concrete to be strong but maintain its sheen. Once the desired gloss is achieved, all the coatings, repellants previously mentioned, and coatings to protect against oil and water can be applied. This is where the colour staining also occurs for aesthetic purposes.